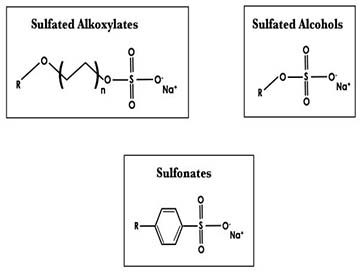

Sulfated fatty alcohols are produced by the process of ethoxylation and sulfonation on fatty alcohols. Fatty alcohols are derived from natural sources like palm kernel oil, coconut oil, rapeseed oil, castor oil etc.

Sulfated fatty alcohols have excellent emulsifying, wetting, lime soap dispersing and foaming properties. They also have high electrolyte tolerance. Alkyl ether sulphated (ethoxylates) also show improved water solubility and resistance to hardness. These products are widely used in emulsion polymerization, cosmetic formulations, detergents and textile industry.

We offer a variety of sulphates based on natural and synthetic alcohols and ethoxylate. One, of our seven plants, has an exclusive facility for sulfonation using Oleum and other sulphating agents.

We also offer phenol and naphthalene sulfonates for leather industry.

DiOctyl Sodium Sulfosuccinate (DOSS) (CAS- 577-11-7) also called docusate sodium or sodium dioctyl sulfosuccinate is a 2-ethyl hexyl diester of succinic acid with a sulphonic acid group as a salt in the sodium form. It has a molecular weight of 444.6 and molecular formula C20H37NaO7S. Docusate sodium is on the WHO list of essential medicines and is used for palliative care (emollient laxative with stool-softening activity) in oral form as a liquid or capsule. It is also used as food additive for its emulsifying and humectant activity and in cosmetics. It has effective wetting property which makes the industrial use in adhesives and sealants, cleaning and furnishing care products(fabric, textile, and leather products), ink, toner, and colorant products (pigment dispersion); laundry and dishwashing products; lubricants and greases; paints and coatings&paper products. It has fire extinguishing properties since in solutions it generates foam and allows water spreading to contain fires. It has been generally recognized as safe (GRAS)for use in carbonated and non-carbonated beverages functioning as a wetting agent or solubilizer for flavor emulsion stabilizers at levels up to 10 ppm.

Dioctyl sulfosuccinate (DOSS) was one of the main components of Corexit® EC9500A, a chemical dispersant formulation used at the surface and at depth during the response to the Deepwater Horizon incident (2010) which significantly facilitated biodegradation of the spilled oil.

The synthesis of DOSS involves reaction of appropriate alcohol (ie2-Ethyl hexanol) with maleic anhydride followed by addition of sodium bisulfite or starting from sulphosuccinic acid and esterification with alcohol. Both processes are well known with several patents (for example US patents 2.028,091; 2,176,423 (1936, 1939, both to americanCyanamid company)and research articles (see Colloid PolymSci (2006) 284: 1333–1337 DOI-10.1007/s00396-006-1519-2). Mixed sulfosuccinates werealso prepared for research applications. For example a series of ethoxylated sodium monoalkyl sulfosuccinate (ESMASS) ester surfactants were prepared by first reacting octyl, lauryl, or cetyl alcohol purifying them and in the second step reacting them with polyethylene glycol (molecular weight 600).

Bis (2‐ethylhexyl) sulfosuccinate sodium salt is used both as dopant and hydrophobizing agent in the oxidative polymerization of pyrole and the polypyrrole grains are used as light-responsive liquid marble stabilizer. In conducting polymers made from polyaniline, use of DOSS as dopant improves the metallic-type conductivity, elongations and thermally more stable than material made with other dopants.

Emulsion polymerization falls uder the category of radical polymerization (initiated by initiator molecule schematically shown as red dots in Fig. 1) that usually starts with an emulsion incorporating water, monomer, and surfactant (example DOSS). Oil-in-water emulsion (O/W) is the most common type of emulsion polymerization. In such case droplets of monomer (the oil) are emulsified (with surfactants) in a continuous phase of water. Briefly the polymerization process may happen when the monomer layer is dispersed or emulsified in a solution of surfactant and water, forming relatively large droplets in water (as seen in Figure 1).Excess surfactant can than create micelles in the water phase. Small amounts of monomer can diffuse through the water to these micelle. Then a water-soluble initiator is introduced into the water phase where it diffuses inside the micelles and reacts with the monomer. An important parameter for reaction of initiator in surfactant micelles rather than in the larger monomer droplet results from their large surface areas.

At Esteem, we have the capability to produce industrial grade DOSS and other sulfosuccinate esters based on our customer requirements. Mostly the sulfosuccinate esters we manufacture may be used in emulsion polymerizations as wetting agentsand in the industrial or domestic uses mentioned in the introduction. A wide range of sulfosuccinate esters based on different alkyl groups and different solvents (water, linear alcohols, PEG/PPG, aromatic solvents) can be manufactured. Contact us with your requirements or ask for technical specification from our customer service/marketing managers.